A hoodie is a popular garment worn by people of all ages, from casual wearers to athletes. It is a versatile piece of clothing, providing comfort, warmth, and style. But have you ever wondered how a simple hoodie is made? The production process involves various stages, from selecting raw materials to manufacturing the final product. This article will take you through the journey of how a hoodie is produced, from the initial design to the finished piece.

1. Design and Planning

The production process of a hoodie begins with its design. Designers and clothing manufacturers often work together to create the style, color, and size specifications. During this phase, a few important decisions are made. For example, the type of fabric used, the type of stitching, and the overall look of the hoodie, including whether it will have a front zipper or pullover style, drawstrings, pockets, or graphics.

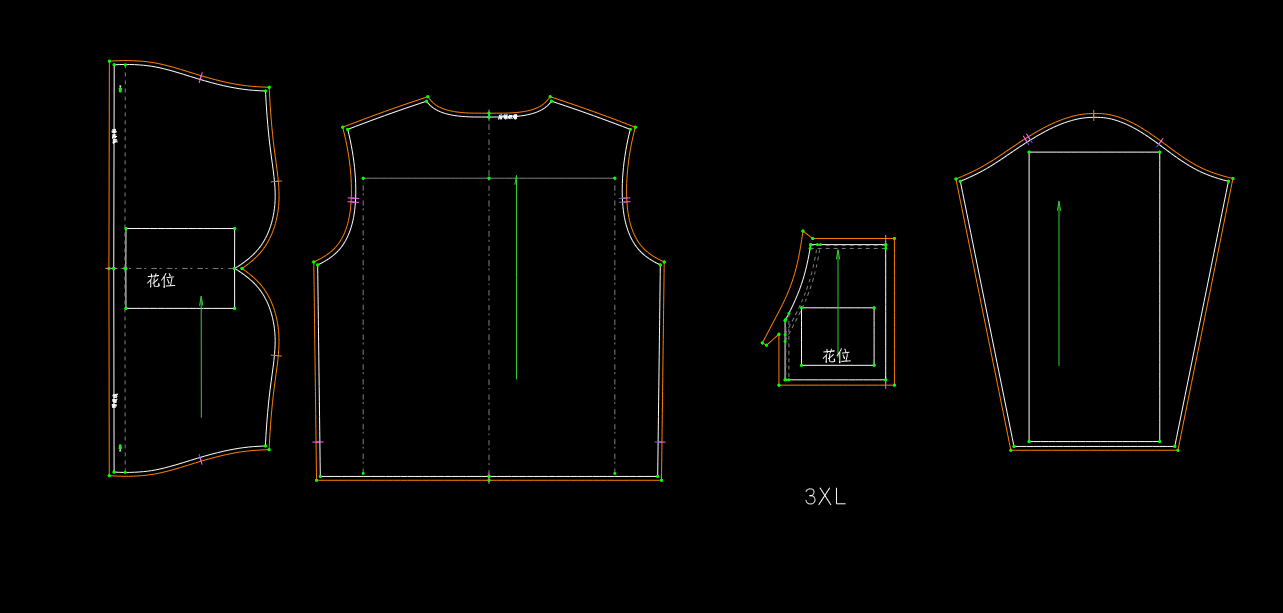

After the initial designs are finalized, the technical aspects, such as measurements and patterns, are drafted. These include a detailed blueprint of the hoodie, including each part such as the sleeves, body, and hood. A sample of the hoodie may be made at this point to ensure that everything fits well and the design is as expected.

2. Material Sourcing

The next step in the process is sourcing the raw materials. Hoodies are typically made from cotton, polyester, or a blend of the two. Cotton is soft, breathable, and comfortable, while polyester is durable, lightweight, and resistant to shrinking. Many manufacturers opt for a cotton-polyester blend, which combines the best qualities of both fabrics.

Once the material is selected, it is sourced from suppliers. The fabric usually comes in large rolls, which are stored until the manufacturing process begins. The material is often pre-treated to prevent issues like shrinkage during washing. This process ensures that the final hoodie maintains its shape after repeated washes.

3. Cutting the Fabric

Once the material has been sourced and treated, the next step is to cut the fabric according to the hoodie design. To do this, the pattern created during the design phase is placed on the fabric, and the fabric is cut into the necessary pieces. This includes cutting the body, sleeves, hood, and any additional parts like pockets or cuffs.

In modern production, this cutting process is usually automated with machines that can cut multiple layers of fabric at once. This method speeds up the production process and ensures that each piece is cut accurately. In smaller or handmade hoodie productions, this step may still be done by hand.

4. Sewing the Pieces Together

After the fabric pieces are cut, they are ready to be sewn together. The sewing process is one of the most critical stages in hoodie production, as it directly impacts the quality and durability of the final product. Skilled workers use industrial sewing machines to stitch the pieces together.

The first step is to sew the sleeves to the body of the hoodie. After that, the side seams are closed, and the hood is attached. The drawstrings are inserted, if the hoodie design includes them, and the pockets are sewn into place. Finally, ribbed cuffs and the waistband are added to ensure a snug fit. Throughout this process, workers must pay close attention to the quality of the stitching to prevent any weak spots that may lead to tearing in the future.

5. Adding Finishing Touches

Once the hoodie is assembled, it undergoes a series of finishing touches. This stage is where small details are added, such as labels, logos, and zippers. If the hoodie has a graphic design or logo printed on it, this is the stage where the printing or embroidery takes place.

Printing methods vary, but the most common techniques used for hoodies include screen printing and heat transfer printing. In screen printing, ink is pushed through a stencil to apply the design onto the fabric. Heat transfer printing involves transferring a design from a special paper onto the fabric using heat and pressure. Both methods ensure that the design lasts through multiple washes.

Embroidery, on the other hand, is often used for logos or smaller text. Using a specialized embroidery machine, threads are stitched into the fabric, creating a long-lasting and high-quality finish.

6. Quality Control and Inspection

Before the hoodie is packed and shipped out, it undergoes a thorough quality control inspection. Workers check for any defects, such as loose threads, broken zippers, or uneven stitching. The hoodie is also checked for color consistency, ensuring that the colors of the fabric and printed designs match the original specifications.

In addition, the fit of the hoodie is double-checked to ensure it matches the sizes outlined in the design plans. This step helps to ensure that customers receive a product that meets high standards and is ready to wear.

7. Packaging and Shipping

Once the hoodie passes the quality inspection, it is ready for packaging. The hoodie is folded neatly, and any additional items like tags or care instructions are included. It is then packed in a protective plastic bag or box, depending on the shipping requirements. The product is labeled with its size, style, and any other relevant information, and is prepared for shipping to warehouses, retail stores, or directly to customers.

Modern hoodie production often involves large-scale manufacturing facilities that produce thousands of units at a time. However, smaller brands or independent designers may have their hoodies produced in smaller batches or in specialized factories that focus on higher-quality materials and craftsmanship.

8. Conclusion

From design to production, the journey of a hoodie is a multi-step process that requires careful planning, skilled labor, and attention to detail. The fabric is carefully chosen, cut, sewn, and finished to create a comfortable and stylish garment that people love to wear. Whether made in large factories or by independent artisans, the production of a hoodie involves a combination of traditional craftsmanship and modern technology, ensuring that each piece meets the needs and desires of customers around the world.

Post time: Jun-12-2025