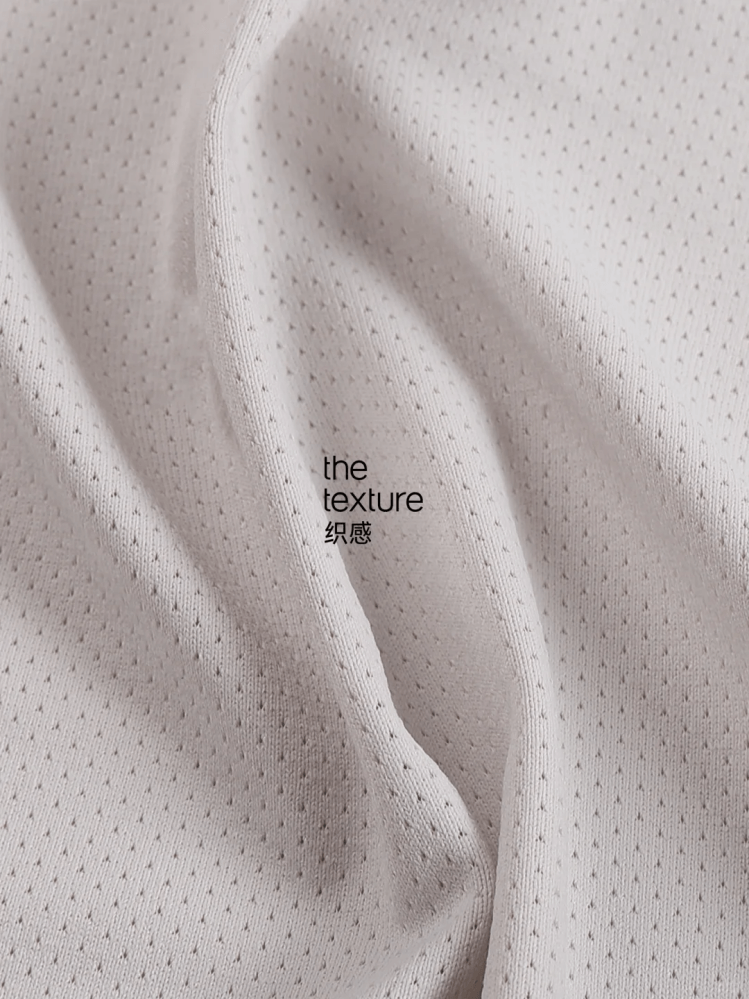

Breathability has become a defining factor in modern sportswear, and mesh jerseys sit at the center of this demand. From professional teams to recreational athletes and lifestyle consumers, expectations for comfort and ventilation are higher than ever. While mesh construction is often highlighted, the fabric used to create mesh jerseys plays a far more decisive role in how breathable the final garment feels. Choosing the right materials can directly affect airflow, moisture control, and overall wearability.

Why Polyester Mesh Jerseys Remain the Industry Benchmark

Polyester mesh jerseys continue to dominate the global sportswear market, largely because of their consistent performance across different climates and activity levels. Polyester fibers are naturally lightweight and hydrophobic, meaning they do not absorb moisture. Instead, sweat is pushed to the surface of the fabric, where it can evaporate more quickly.When engineered into open-knit or perforated structures, polyester mesh jerseys allow steady airflow while maintaining durability. This balance makes them suitable for high-intensity sports such as basketball, football, and running. In recent years, advancements in yarn technology have further improved breathability, with finer filaments creating softer fabrics without restricting air circulation. For brands focused on scalability and reliability, polyester remains the most practical fabric choice.

How Nylon Mesh Jerseys Enhance Lightweight Breathability

Nylon mesh jerseys are often associated with premium performance, offering a slightly different feel compared to polyester. Nylon fibers are smoother and more elastic, which contributes to a lighter, more flexible garment. This can be especially beneficial for athletes who prioritize unrestricted movement and reduced skin irritation.

In terms of breathability, nylon mesh jerseys perform well when designed with larger mesh openings or engineered ventilation zones. Nylon also dries quickly, helping maintain thermal comfort during prolonged activity. Its superior strength and abrasion resistance make it a preferred option for sports involving frequent contact or repeated washing. Although production costs are typically higher, nylon mesh jerseys are increasingly used in high-end collections where performance and comfort justify the investment.

The Role of Fabric Blends in Breathable Mesh Jerseys

Blended fabrics play an important role in improving the overall functionality of breathable mesh jerseys. By combining polyester or nylon with fibers such as spandex or elastane, manufacturers can enhance stretch and recovery while preserving airflow. These blends allow mesh jerseys to fit closer to the body without trapping heat, reducing the discomfort caused by heavy perspiration.

In some cases, small amounts of cotton or regenerated fibers are introduced to improve softness and tactile appeal. While pure cotton is generally less breathable for athletic mesh jerseys due to moisture retention, carefully engineered blends can offer acceptable ventilation for lifestyle or training-focused designs. For brands targeting both performance and everyday wear, blended fabrics provide a flexible solution.

Sustainable Fabrics Are Reshaping Breathable Mesh Jerseys

Sustainability is increasingly influencing fabric selection, and breathable mesh jerseys are no exception. Recycled polyester has become a widely adopted alternative, offering comparable breathability and moisture-wicking performance to virgin polyester. When processed correctly, recycled fibers maintain airflow efficiency while reducing environmental impact.

Other developments include bio-based synthetics and low-impact dyeing techniques that preserve fabric performance. As buyers and consumers place greater emphasis on responsible sourcing, breathable mesh jerseys made from sustainable fabrics are gaining traction across global markets. Breathability is no longer viewed solely as a functional feature—it is part of a broader product story that includes environmental accountability.

Conclusion

The breathability of mesh jerseys depends as much on fabric choice as it does on construction. Polyester mesh jerseys continue to lead due to their versatility and cost efficiency, while nylon mesh jerseys offer enhanced comfort and durability for premium applications. Fabric blends allow brands to fine-tune fit and flexibility, and sustainable materials are redefining how breathable mesh jerseys align with modern market values.

For manufacturers, brands, and buyers, understanding these fabric differences is essential when developing mesh jerseys that meet performance expectations and evolving consumer demands. As the sportswear industry moves forward, breathable fabrics will remain a key factor in delivering comfort, functionality, and long-term value.

Post time: Jan-23-2026