1. Wash

In clothing, some hard fabrics need to be washed to make the fabric softer. Denim fabrics and some clothes that need retro style will be washed.

2. Pre-shrink

Pre-shrinkage is the shrinkage treatment of fabric, which aims to make the fabric shrink a certain amount in advance in the warp and weft direction, so as to reduce the shrinkage rate of finished products and meet the quality requirements of garment processing. When you buy some clothes that are not very good, it is impossible to wear them after washing them once, that is, they are not pre-shrunk before the sale of finished products. But not all fabrics are required to pre-shrink, the specific or depending on the fabric

3. Embroidery

Embroidery is to embroider on the fabric. Specifically, it depends on the pattern of your design. Generally, you will go to the embroidery factory for processing.

Many clothing brands will use it, such as; Gucci will also use some Chinese-style clothing, and many furniture items will have embroidery techniques.

4. Hot drill/hot pattern

This is a pattern can be directly ironed on the desired position, simple and easy to operate, this can be completed by itself.

5, offset printing

Offset printing is a lot of T-shirts, hoodies will be used on the above, the pattern on the clothing.

6, digital hot pad printing

Digital thermal pad printing is a combination of traditional heat transfer technology and digital printing technology, which requires high temperature resistant fabrics and fabrics with high polyester content, suitable for mass production, but long cycle.

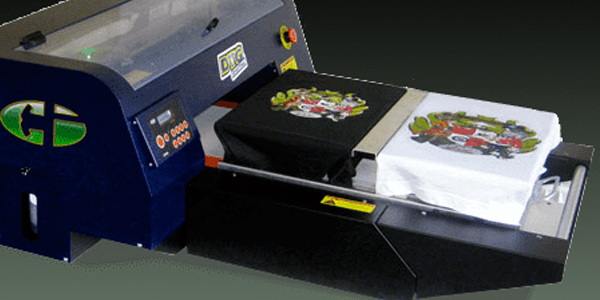

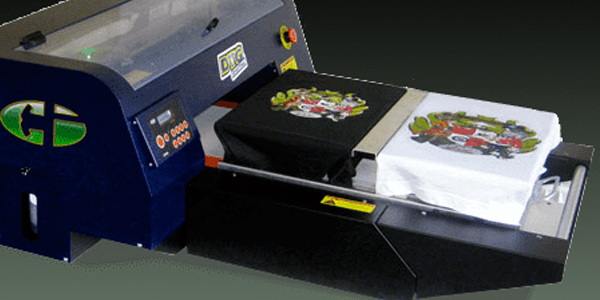

7. Digital direct spray print

Digital direct spray print is a good pattern processing process, high color saturation, pattern expression is also good, suitable for some expensive clothing. After all, the price of digital direct injection is not cheap, or need to consider the cost accounting

Post time: Jan-04-2023